Table of Contents

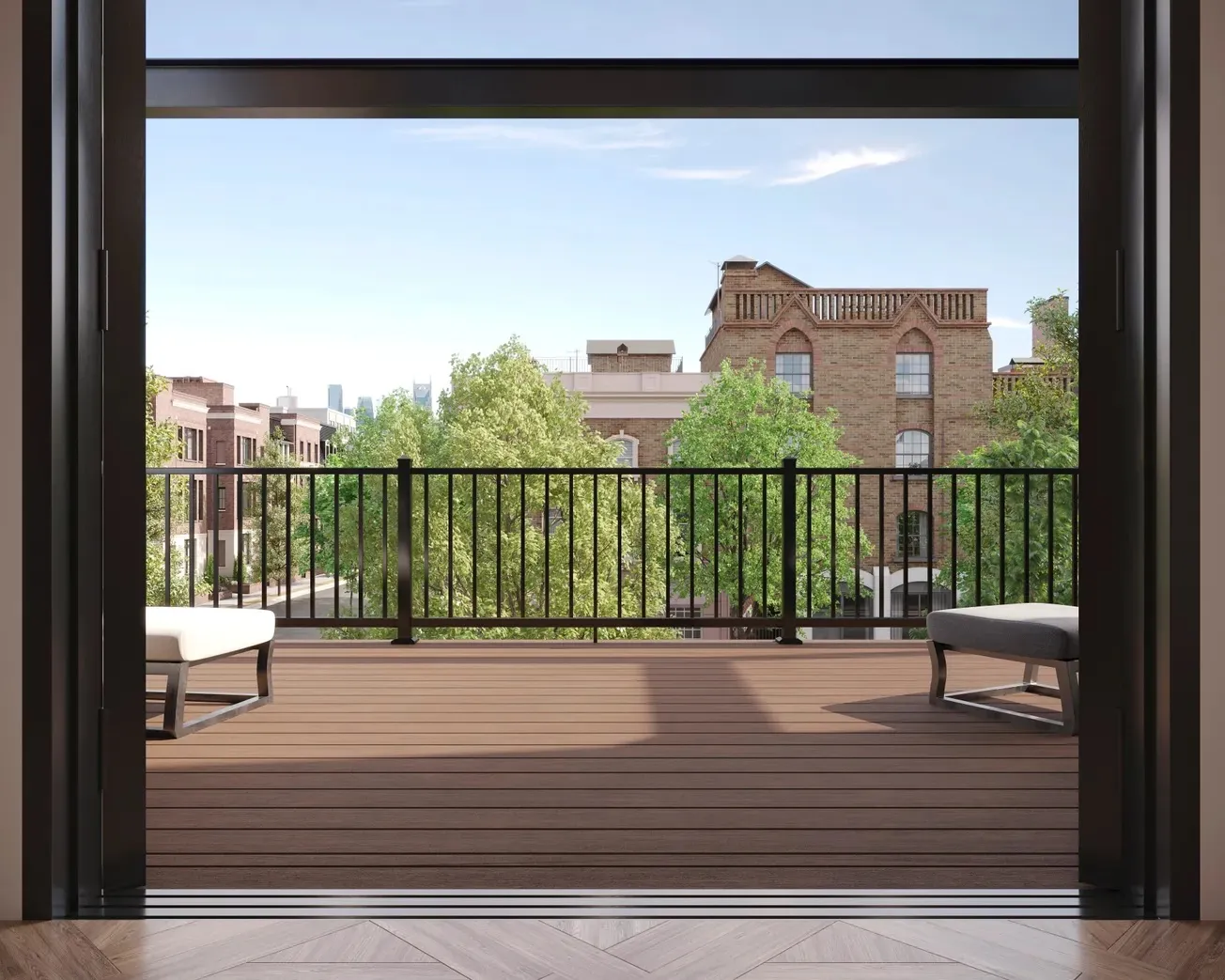

While homeowners lounge on their luxe outdoor couches or roast s’mores with the family around the deck firepit, they often take for granted the importance of the structural framing systems that are making it all possible. For decades, traditional wood products used in deck construction quickly succumbed to the elements to which they are so frequently exposed: sun, insects, rain, snow and natural organic breakdown of the material.Recently, engineered wood manufacturer Pacific Woodtech (PWT), a Burlington, WA.-based company, unveiled a treated deck solution that addresses the critically important structural framing systems that support everything else. PWT Treated LVL is the world’s first manufacturer-treated laminated veneer lumber. For all the same reasons engineered wood products have become immensely popular in interior residential framing (40% to 50% market share), they are becoming increasingly sought out for exterior framing needs.

Bigger Building Options

PWT Treated allows designers to greatly increase the scale of exterior framing projects in many of the same ways they have been able to do in the interior. Step outside to enjoy larger open areas. Take in grander vistas by decreasing the number of posts, columns or larger overhangs and balconies, and save time and money by reducing the number of energy-intensive footings that need to be installed.

Sturdier Products

Treating LVL with conventional methods for dimensional lumber weakens the structure of the product. Fortunately, PWT discovered Kop-Coat’s Tru-Core technology, which fully penetrates each veneer layer to the center then adds an envelope finish to protect each piece from the inside out. Every beam, joist and column suffers no loss of properties, and is safeguarded against damage caused by fungal rot, decay and insects. The final product, explains PWT’s Matt Caissie, “is just as strong as it was pre-treatment, and that gives us the ability to create long spans. Designers can run wild with the structural capabilities of the product, open up sight lines below-deck, and really match up better to the high-end composites that are on the market today.” Additionally, PWT Treated contains no additional volatile organic compounds (VOCs), and can be used both inside and out where projects call for joists to be cantilevered outside of the building envelope, creating zero-support balconies.

Your Crew Will Thank You

In recent years, several composite decking manufacturers have worked to fill the niche for higher-end, warrantied framing by introducing steel deck framing systems (namely Trex’s Elevations and Fortress’ Evolution systems).

Installing metal framing, however, does require different expertise and tools than a small deck crew may possess. PWT Treated can be drilled, ripped, tapered and cut to length just like dimensional lumber. The product is lightweight and easy to handle. It allows building designers and structural engineers to work with published structural design properties to create structures that far exceed code requirements. Eased edges are applied to the beams and joists, meaning construction crews avoid splinters. It can be safely discarded with regular household waste, making job site cleanup simple and easy.

Design with Ease

The full lineup of PWT Treated products can be designed using a layout, estimating and engineering software package called iStruct. This one-stop shop makes it easy for your architect or designer to communicate with your build team, while keeping the project on time and on budget. Use iStruct to select the best products for the design, run calculations to see how the wood will perform, generate 3-D renderings to help owners visualize the project and create a full bill of materials, including hangers and accessories.

The Best Deck Possible

With the outdoor living trend firmly on the rise, it makes perfect sense to ensure these premium spaces and materials rest on the best structural weather-treated framing products on the market. “We try to promote a system that is better than code-minimum,” Caissie says. “For years, folks have leaned on the deck installer or the code documents to say, ‘Here’s how we’ll build this frame.’ We have the ability to run this product in the software the same way we do our interior products and create code-improved products that are stiffer, stronger and can handle heavier loads like a hot tub or an outdoor kitchen.”

That should translate to bigger ticket decks, he says. “Every single contractor will have an opportunity to upsell to something better that’s still easy to work with. “And when you look at the cost of the decking, railing, lighting, furniture, hot tub, barbecue, it’s a real small upgrade to have a greatly improved framing system beneath it all. I think it’s going to catch on pretty quickly. The same way we see that interior frames are now 50% engineered, that would be an amazing goal to get there on the exterior.”Boasting a 25-year warranty, the framing system includes ledgerboard, deck joist, deck beams, columns and stair stringers. They can be factory- or field-laminated. Offered are billet beam sizes of 3-½”, 5-¼”, and 7”, plus 1-3/4”, which can be bolted, nailed or screwed together, for crews that want to handle smaller pieces rather than a larger section.PWT Treated is sold through a network of engineered wood distributors who will assist with design and delivery to builders’ local building material dealer.

Make homeowners even happier with a long-lasting, beautifully crafted deck that invites everyone to stay a little longer, watch the sunset, and then maybe enjoy some s’mores under a starry sky.