Flex Power Tools at JLC

It will demo its 24V cordless power tool lineup, debut its revolutionary Track-Lock wall-mount system, and the launch new drywall sanders.

It will demo its 24V cordless power tool lineup, debut its revolutionary Track-Lock wall-mount system, and the launch new drywall sanders.

Feeney’s Annual Photo Contest Highlights Exceptional Work by Design and Construction Professionals Across the Industry

Acquisition of Minneapolis Metro area specialty decking materials supplier furthers Decks & Docks’ Midwestern expansion and growth

The branch will operate under The Rock Place brand.

The industry’s largest and longest running contractor program.

January/February 2026 issue of Deck Specialist, a trade magazine for outdoor living professionals.

November/December 2025 issue of Deck Specialist, a trade magazine for outdoor living professionals.

September/October 2025 issue of Deck Specialist, a trade magazine for outdoor living professionals.

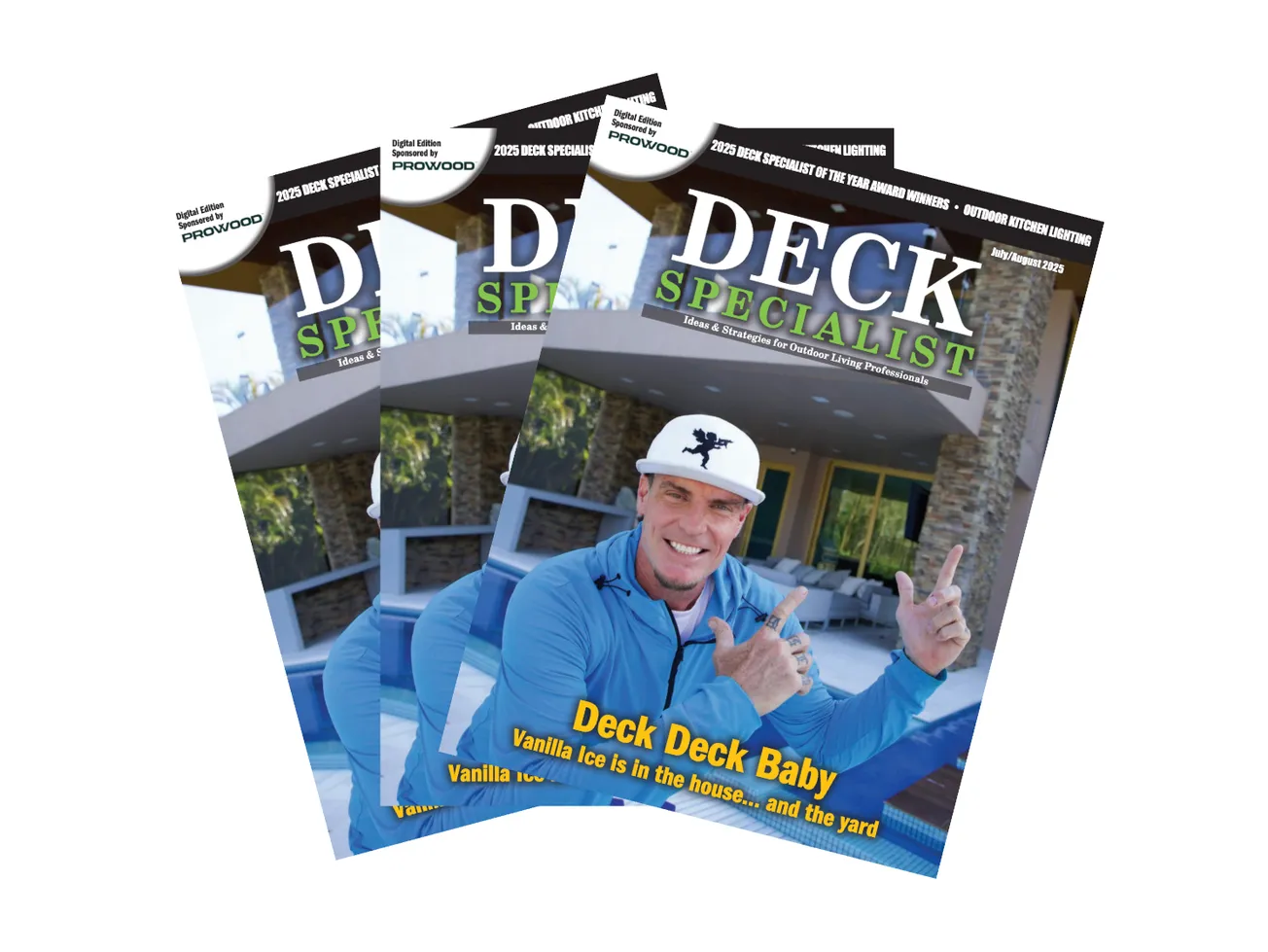

July/August 2025 issue of Deck Specialist, a trade magazine for outdoor living professionals.

Deck Specialist columnists Andy Henley and Mike Mitchell look forward to the upcoming Deck Expo show in Las Vegas

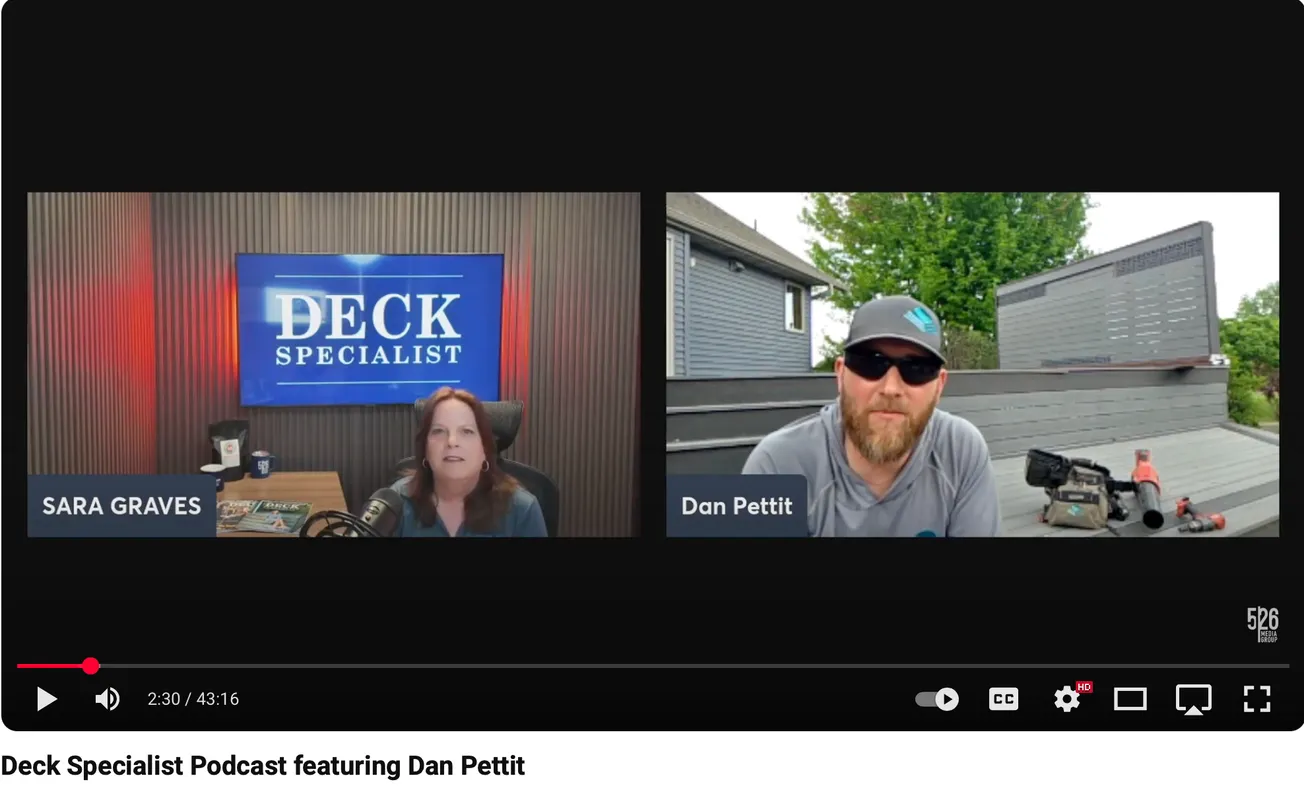

Minnesota deck builder Dan Pettit shares how storytelling, precision, and collaboration fuel his high-end outdoor living projects—and how he’s connecting with pros nationwide through passion and craftsmanship.

Vanilla Ice kicks off the Deck Specialist podcast with a look into his second career as a luxury builder.

Sponsored by ProWood

Sponsored by Deckorators®

When you’re building a deck that’s expected to hold up to years of weather, wear, and client expectations, your substructure matters just as much as the finish work. At ProWood®, we understand that durability, safety, and long-term performance aren’t optional—they’re essential.

A space that must be seen, touched, and stood upon to be believed. The decking bar has been raised, and the difference is unmistakable. You can be sure of it. Surestone®.

It will demo its 24V cordless power tool lineup, debut its revolutionary Track-Lock wall-mount system, and the launch new drywall sanders.

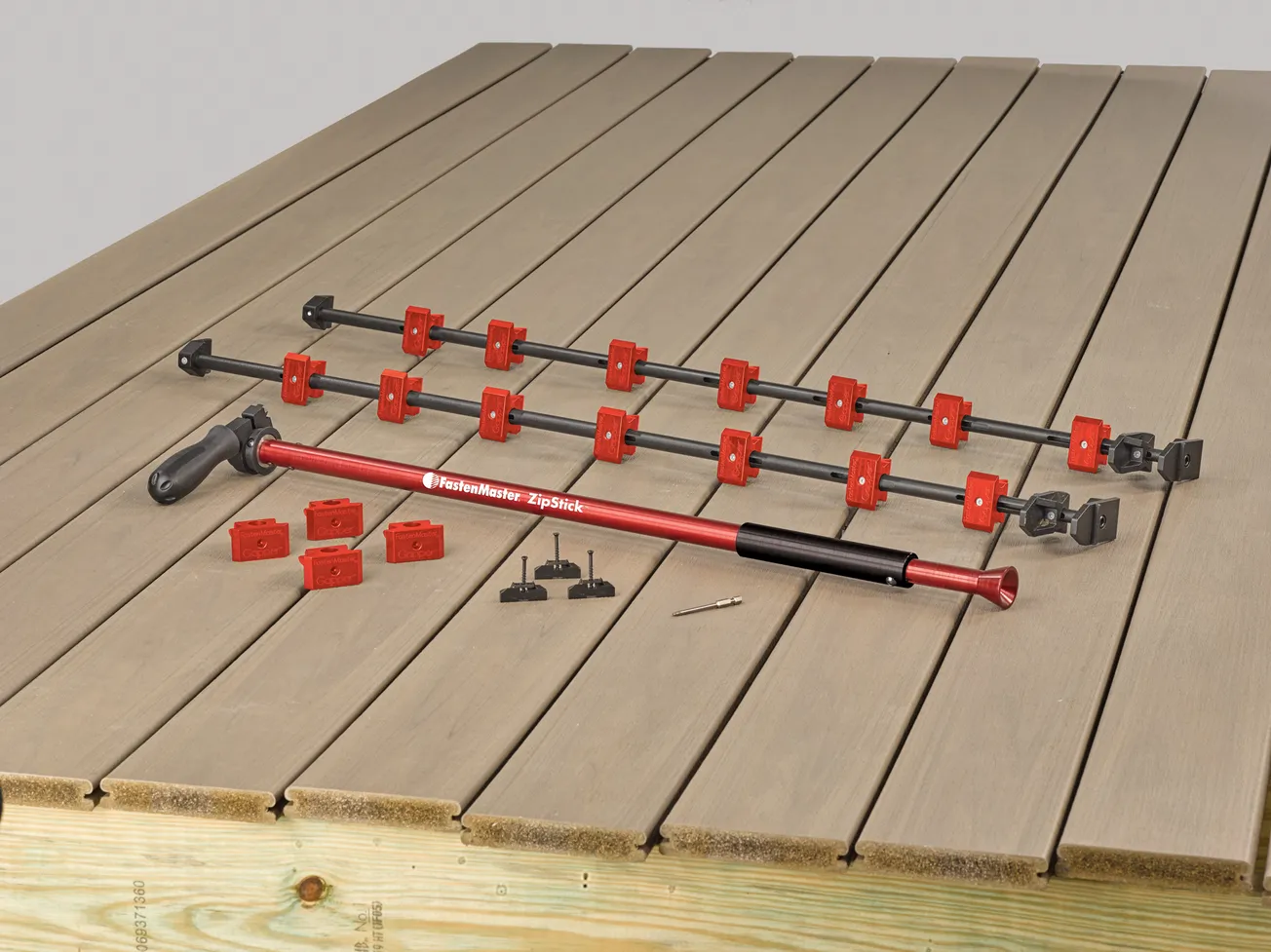

The new Zip Hidden Fastening System is compatible with leading grooved composite and PVC decking boards, including Trex, Deckorators, and Fiberon, and more.

Digger Specialties Inc. introduces Westbury aluminum post wraps, offering durable, low-maintenance upgrades for decks and porches with premium finishes and easy installation.

The companies intend to accelerate the growth and adoption of ThermoWood thermally modified wood in the North American market.

The industry report breaks down what shifting market conditions, supply chain realities, product innovation, and workforce trends.

He will serve as a key spokesperson with investors, analysts, and financial media and execute the company’s corporate development strategy, leading the end-to-end M&A process.

PrimeSource Building Products has launched the Wolf Outdoor Living brand, bringing railing, decking, and exterior finish collections together under one reliable source.

The product was named a finalist in Best of IBS Awards in Best Outdoor Product.

The French countryside project featuring Kebony’s dually modified wood terraces was a former farmhouse with a 12th Century watchtower.

Nova USA Wood is pleased to announce that Ambara, its thermally modified cladding product, has received an official California State Fire Marshal (CSFM) Building Materials Listing (Listing No. 8140-2377-0003) for use in Wildland-Urban Interface (WUI) applications. Ambara has been tested and certified to CSFM 12-7A-1 and is compliant with Chapter

This upgrade reduces the noise often associated with walking on aluminum decking, offering a more comfortable and quiet outdoor experience for residential, marine, and multifamily spaces.

The most successful custom deck projects begin with a clear vision and a collaborative relationship between homeowner and professional deck builder.

The newly launched TrendLine platform translates consumer data and expert insights into an interactive guide for ‘intentional home’ design

Planning a backyard deck in 2026? Discover modern deck design ideas, outdoor living trends, durable materials and layout strategies that balance beauty, performance and long-term value for your custom outdoor space.