Table of Contents

While decks are a key part of any outdoor space, railings are an equally important component in creating a deck that looks great while also offering the durability and functionality that today’s homeowners expect. Although many consumers still opt for wood railings, composite deck railings are gaining traction. They may be more expensive than wood at the outset, but their benefits – resistance to the elements and a significant reduction in long-term maintenance costs – make this railing type increasingly attractive. In addition, composite rails are available in a variety of styles and colors, providing design versatility.

Homeowners seeking to optimize their view are typically drawn to more minimalistic railing types – for example, stainless steel cable rail infill, which offers a very clean, streamlined look. While cable infill is frequently used with wood posts, it has been – until recently – challenging to install cable infill in a frame with composite sleeved or wrapped posts.

Recognizing the growing demand for composite deck components, Feeney has developed a solution for railing projects pairing its CableRail infill with composite components. Feeney’s patented Quick-Connect® Lag and Pivot fittings have been specially designed for attachment to wood posts with a composite sleeve or wrap. These easy-to-use fittings attach to the inside faces of the posts, simplifying installation for both level and stair railings.

- Before starting your project, be sure to check with the composite manufacturer and your contractor to confirm that the frame materials and railing design can support the tension loads of Feeney’s CableRail infill.

- Feeney’s Quick-Connect® Lag Fittings (recommended solution) come with a hanger bolt. The lag threads screw into the core post, and the machine threads attach to the fitting. Make sure there is a solid wood core inside the composite sleeve or wrap for the lag threads to engage. Good thread engagement within the wood core will provide the necessary pullout strength to enable the cables to be properly tensioned.

- Feeney’s Lag fittings come with hanger bolts in two different lengths. When installing CableRail in wrapped or sleeved wood posts, choose the longer hanger bolt (with 2-1/2” of lag thread) to allow enough length to adequately penetrate and clear the composite material. Many composite wraps have built-in ribs that will touch the wood post on the inside, which helps to eliminate gaps and strengthen the post.

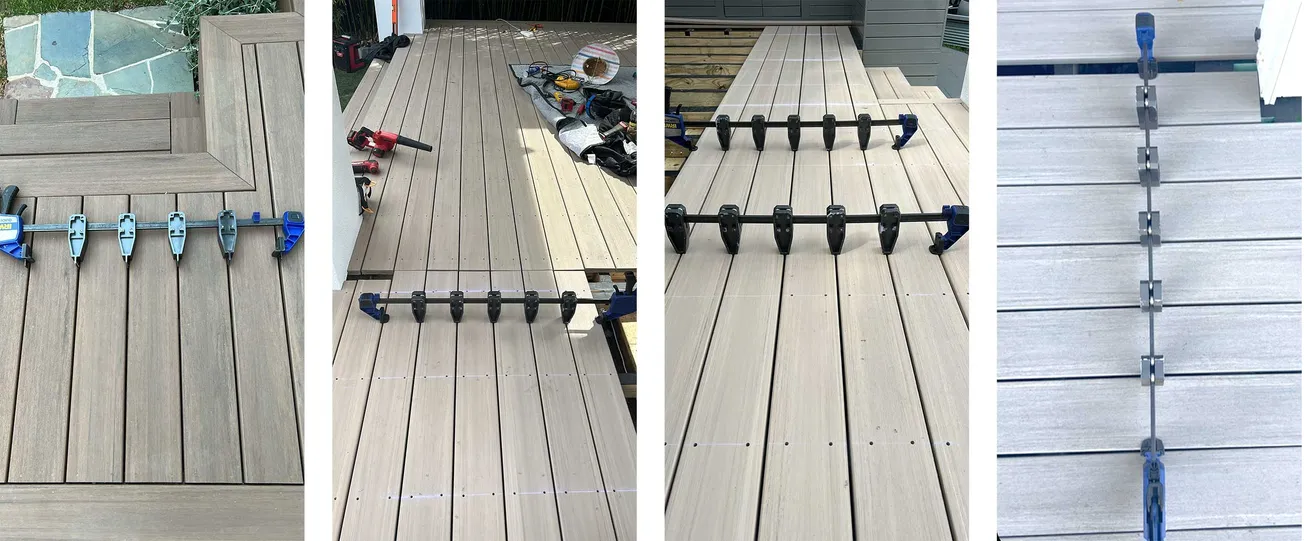

- Installing Feeney Intermediate Pickets mid-span will provide additional support for the cables between the sleeved posts. If you are using a Feeney pre-drilled Intermediate Picket, use it as a template to mark all drill holes along the center line of the inside faces of the termination posts. If you are using an undrilled picket, measure and mark holes that are no more than three inches apart, and make sure the top and bottom cables are three inches or less from the top rail and bottom rail or deck.

- To prevent the cable from snagging on post holes, it is recommended to use Feeney’s Cable Lacing Needle for threading cables through intermediate posts and pickets.

- When tensioning the cables, start at the center cable, alternating top to bottom until all cables are tightened. Be sure to follow the suggested tensioning sequence to minimize stress on the railing frame and easily adjust uniform tension across all of the cables. Feeney’s CableRail Tensioning Tool and Tension Gauge can be used for faster, more efficient tensioning.

For more tips and a step-by-step guide to installing Feeney’s CableRail infill with composite sleeved or wrapped posts, see our video tutorials.

View drone footage of a recent large residential entertaining deck that features Feeney CableRail and Trex composite railing. Nestled in the hills of Anaheim, California, the expansive deck more than doubled the homeowner’s outdoor living and entertaining space.

To learn more about Feeney’s CableRail solutions, visit feeneyinc.com/CableRail.