Table of Contents

Last time, I discussed marketing and how to get leads coming your way. Hopefully some of what you read will help you in the future in your marketing. Remember that each part of your business works with another. They are all tied together, and you have to master each one or hire someone who can. Today we are going to talk about how the lead turns into a quote, but more about how to make your quoting process more efficient.

Can you price out a deck in the living room off of a sketch? Can you do that the minute after you measured and discussed the area? If not, you may want to learn how. The first steps were mentioned in my previous articles (material supply consistency, narrowing down offerings, etc.). In the future, we will also talk about paying subs and employees to get your costs fixed.

So, if I have a deck that is overall 200 sq. ft. of the products I want to install, and I know my costs going into the house, why not quote it on the spot? After all, I’ve built that combination of materials in different shapes all year. Your competitor is going to go to that same house, have similar discussions, take notes, leave, go home, sit down, do a takeoff, send it to the lumberyards to bid, wait to get it back, then try to put it into some form of a quote, go back to see the customer, then vomit that quote all over them. This whole process takes that guy a week at the minimum, if he shows up. When he does, the quote will say, “Blah blah blah deck… $10,000.”

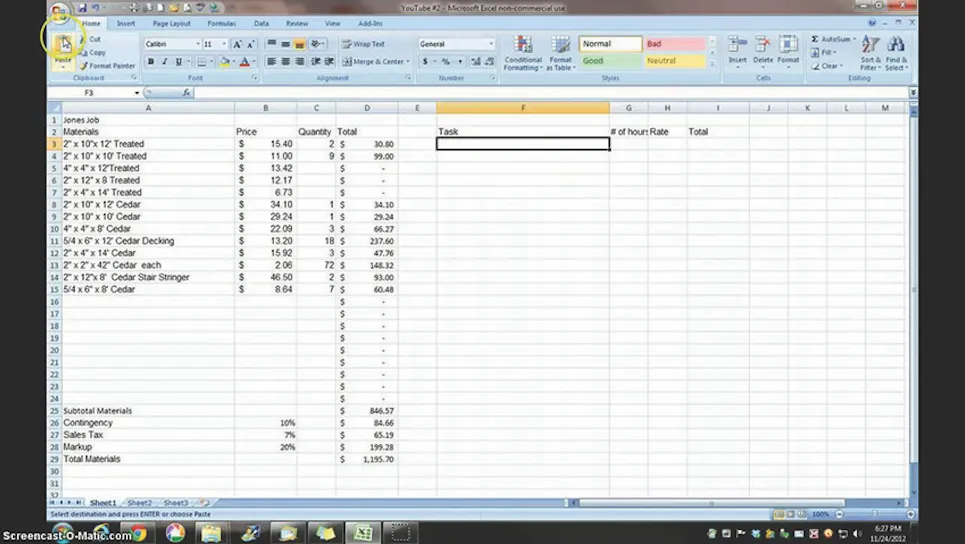

You on the other hand will have a template quote in your computer that you will add line item pricing to. Such lines are “Square feet of deck,” “number of steps,” “linear feet of railing,” “number of newels,” “feet of fascia,” feet of single inlay,” “feet of double inlay,” “feet of double curved border,” etc, etc. This breakdown of accessories and parts helps your customer break down where the money is going in the project and rationalize why it costs so much more money than they were expecting. On the simplest of decks, my itemized list was about six lines, then a total.

At one time, I quoted all decks with financed pricing as well, so rather than saying the deck is $8,000, I told them $156 a month for 60 months, interest free if paid off in 12 months, or if they preferred to pay by check $8,000. On the other really important stuff like how you are framing the deck, methods of construction, etc., all of this will be in the quote form already, so you are only filling in the costing. This entire document should be done in Adobe or some other editor that you know how to use, and have a signature pad or touch screen monitor so you can get a signature.

The days of hauling a printer around in your car are over. DO NOT print your quote out and hand it to them without telling them the price. Get good at breaking the news. You have to tell them they are going to spend $80,000 with soft arrogance and confidence. I always discussed the scope of work, showed the designs, explained that the final design would be tweaked, and they would approve it before we got started, but once they committed to the project. I also offered a cash price and a credit card price, explaining that there is a bank fee that we are charged. I went through all of that.

You can charge more when you quote on the spot! You can charge more than everyone in town because you are the doctor who just showed up and treated the patient in the living room. These people decided to add a deck and are ready to pull the trigger (if they aren’t, wait for the sales article or go back and read about pre-qualifying your customers).

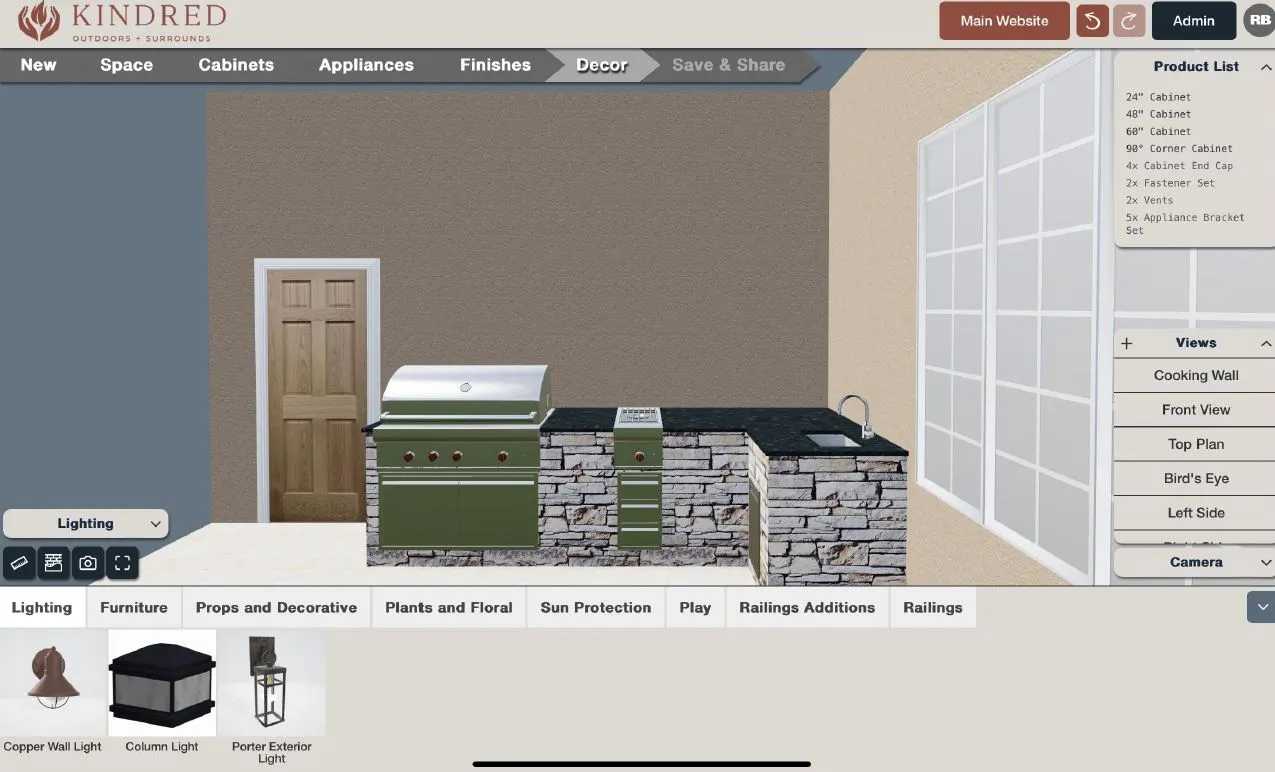

Many times, I went to a home, looked at the area, looked at the napkin sketch the customer did, opened my laptop to my 3D design software, drew the basics of what I was thinking, and gave them a quote. Whole process under two hours. I’d then get them to agree to do it, sign a basic contract, get a deposit, and then go back and do all of the other work (fine-tuning the drawings, doing takeoffs, etc.). Why would you ever do a takeoff on a job you don’t have sold, or ask your lumberyard to do it? Why dump the time into it if you aren’t sure you’re getting compensated for that time?

Here’s a thought: Doing it the hard way, a quote likely will take a combined six to eight hours. You can do it in two. Now, grab your calculator and see how the profit from the job you will sell divides into two hours. Now assume you sell 50% of every lead you run in two hours or less. How many more leads can you run? How much money will you make hour now? Now ask yourself if that guy you are quoting against is actually competition. While you are playing with your kids, he’s calling the lumberyard asking where the heck his framing quote is.

Quoting process needs to be efficient and fast. If what you are doing is not, re-think your process.