Table of Contents

While demand for new outdoor living spaces is strong, the scarcity of skilled workers has many deck contractors booked out for months and losing out on significant revenue opportunities. Often there is not enough capacity available for follow-up on new leads, stunting business growth.

“Every year, fewer young people consider careers in the building trades,” says Kat Williams, senior business manager for Deckorators, a leading manufacturer of composite decking, railing and related products. “Today’s society pushes high school graduates toward a traditional college environment, no matter what their interests. This trend has led to a costly trade skills gap in our industry—and we’re all looking for ways to narrow that gap.”

Following are three ideas to create capacity for deck builders feeling the effects of the labor crunch:

- Apply for an apprenticeship program.

Williams says members of the Deckorators Certified Pro deck contractor program have repeatedly raised concerns about the skilled labor gap—at builder workshops, during the Deckorators Pro Summit, and on jobsites around the country. Her team wanted to be part of the solution to the issue.

That’s why the company recently launched the unique Deckorators Deck Builder Summer Apprenticeship Program, which matches Deckorators Certified Pros with vetted and trained local apprentices. To land apprentices who can extend their crews and boost production, Certified Pros go through a straightforward process including application, recruitment, training and the apprenticeship period.

The HR team at parent Universal Forest Products helps approved Certified Pros with recruiting local apprentices by:

- Working with the Certified Pro to develop a job description.

- Advertising locally on Facebook, LinkedIn and Craigslist.

- Reaching out to colleges, universities and tech schools.

- Performing in-depth interviews.

- Reviewing references.

Pros have the option to conduct their own final interview prior to approval. Mike Brueggenjohann, a consultant at California Custom Decks, St. Louis, MO., participated in the apprenticeship program this summer. The Certified Pro says the program helped address his two biggest labor challenges: recruiting the right people and providing proper training.

“Deckorators found our apprentices and helped us give the right people a chance—without bogging us down when we were busy and unable to invest the time into recruiting,” Brueggenjohann says. “Then, the individualized apprentice training with an experienced Deckorators representative was invaluable. It instilled skills and confidence under the best conditions possible.”

Just 60 days into the apprenticeship period, Brueggenjohann hired an apprentice on full-time, removing the apprentice label due to the employee’s attitude, work ethic, and development. He recommends that contractors strapped for labor consider applying for an apprenticeship program.

“Our experience has been very successful,” he says. “The goal with our apprentices and hiring in general is to recruit the right people with the mindset of learning and applying their skills so they can develop into the best carpenter they can be. This program feeds right in to that approach.”

Williams says the inaugural year was just the beginning for the apprenticeship program, with significant program evolutions coming in 2020.

“Many contractors lack the resources to recruit quality labor, so they take the help that’s available, regardless of fit,” Williams says. “This forced approach to hiring can lead to turnover and jobs taking longer to complete. The addition of quality labor through an apprenticeship program can help deck builders bolster their crews, increase production, and devote more time to closing interested leads.”

- Seek help in unusual places.

Cass Brinkman has managed to avoid the labor woes plaguing so many of his peers. The owner of All Weather Decks, which builds around 350 decks per year in the Kansas City, MO., metro area, he attributes part of his success with finding good help to thinking outside the industry.

“One of my best deck builders had never built a deck in his life before I hired him,” says Brinkman, another member of the Certified Pro program. “I brought him in from the stone masonry industry, trained him on the job site, and positioned deck-building as a new career opportunity for him. He took that very seriously, and he’s been with me for 10 years now.”

Brinkman regularly asks crew members for referrals, and pays referral bonuses of $100 for a helper and up to $500 for each lead that comes and stays aboard. All Weather Decks currently has 15 two-person crews with each crew lead providing continuing education to the helper.

Once quality workers are in the fold and training, Brinkman focuses squarely on providing them with steady hours and a consistent paycheck. “I know if I solve those two problems, they will stay with me forever,” Brinkman says. “They feel such stability and trust that they don’t have a reason to look anywhere else.”

His commitment to finding—and retaining—good labor has helped make All Weather a top custom builder in the area, a 20-time winner of the Angie’s List Super Service Award, and a perennial Best of Houzz winner for service and design.

Despite an extremely slow start to the deck-building season due to an extended winter, All Weather Decks is ahead of last year’s sales pace. Brinkman says his sweet spot is being booked out between six to eight weeks. Any longer than that, he searches out another crew; any shorter, he steps up advertising and sales training.

“I try to create a situation where I don’t have a labor shortage,” Brinkman says. “I can’t grow if I can’t get enough crews, so I refuse to accept a labor problem as my fate.”

- Use more labor-saving components.

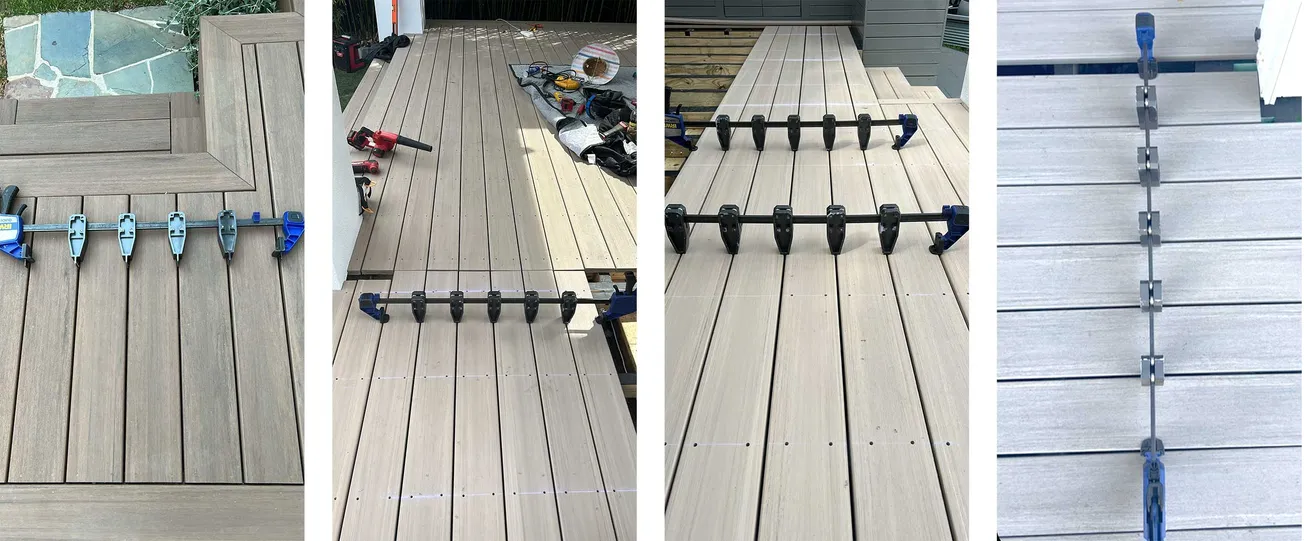

As the trade skills gap continues to challenge the decking industry, manufacturers are working to incorporate more ease of installation into their product designs. Contractors can benefit by adding more of these products to their portfolios.

“There are more products out there than ever before that help pros build faster, close jobs more quickly, and create capacity,” says Jase DeBoer, senior category marketing manager for Deckorators. “The exciting thing is that aesthetically these same products are still very much on-trend.”

Examples of attractive products that speed up installation include stronger, lighter composite deck boards; pre-assembled railing systems that come to the site with the top rail, bottom rail, and balusters already installed together; and low-voltage lighting offering simple wiring. Some lighting offers a straightforward clip system in which each component’s clip simply plugs into a junction box, making installation as easy as connecting a telephone cord to a phone jack.

Many builders would embrace the opportunity to meet rising demand for personalized decks—if only they had the qualified labor to build them. Signing up for an apprenticeship program, broadening the search for help, and using contractor-friendlier products can help.

For more info on Deckorators’ programs for deck builders, visit www.pro.deckorators.com.