Table of Contents

It is no secret in the corporate world that providing inviting break areas can help reduce stress, promote mental clarity, and enhance overall employee well-being and productivity. With its commitment to employee well-being and engagement in mind, OMG Building Products, LLC, has completed construction of a new deck and pavilion at its headquarters facility in Agawam, MA.

Designed by the OMG’s FastenMaster Division, using many of the company’s decking products, and built by company employees as a training project, the new 1,300-sq. ft. structure includes two levels, as well as a roof with a cupola over the largest portion. In total, the structure is 54-ft. long by 24-ft. wide with a roof over the 34-ft.-long upper level. The 20-ft. long lower level is uncovered.

“We are very excited about the new pavilion,” said Shaun Jennings, senior marketing manager. “Not only will it provide great space for breaks, informal meetings, and employee collaboration, but it’s also an ideal space for the many employee events we hold here in Agawam, including cookouts, movie nights, tag sales and open houses.”

From the outset, the OMG deck was designed to be minimally disruptive to the surrounding area. For example, rather than digging up the site and installing large tubes for traditional concrete footings, the pavilion is supported by a series of helical piles. Helical piles or screw piles are round steel shafts about 10-ft. long with a helical bearing blade that are screwed into the ground to support and disperse the structure’s weight.

Once the 34 helical piles were installed, triple 2x10 beams were set across the helical piles 10 ft. apart to support a hybrid joist system engineered to combine the strength and durability of steel with the lightness and workability of wood. In addition, the hybrid joists provide a consistently level deck surface without crowns or low spots that occur with traditional 2x lumber.

“One of the best parts of this project was that it served as a company training project for our employees,” said Jennings. “Not only was it a practical design experience for the design and product management teams, but also we were able to showcase many of our new products and fastening technology to the manufacturing team so they would better understand how and where FastenMaster products are used in the real world.”

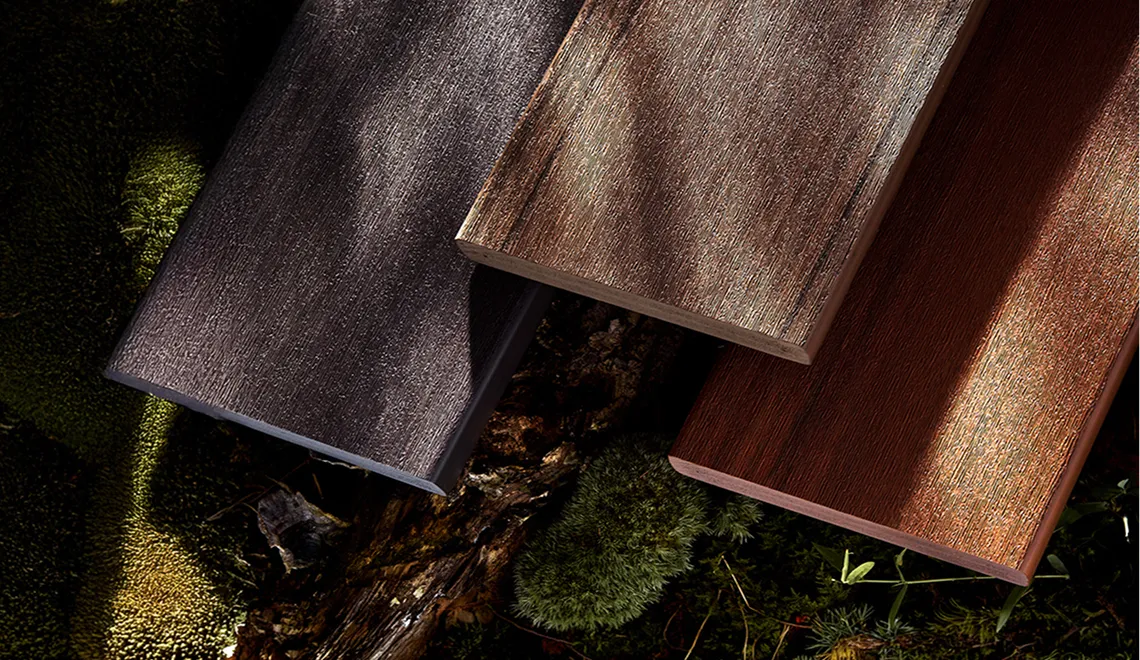

The deck, which is finished with composite AZEK/TimberTech decking, includes a handicap ramp as well as three sets of stairs. The decking was installed using FastenMaster’s stainless steel Tiger Claw Hidden Fastening clips, for a clean, fastener-free look. In addition, a 10-ft. diameter company logo was installed in the center of the upper deck using contrasting-colored materials, some of which had to be heated to over 200°F and hand curved on site to create the company’s round logo. The materials for the logo were installed with FastenMaster’s Cortex Hidden Fastening system, where plugs made from the composite material are inserted over the fastener head to ‘hide’ the fasteners and provide a clean finish.

In addition, several other FastenMaster products were used to build the deck including the new Deck Frame Coating, which was applied to the substructure to create a protective moisture barrier that deters rot and decay on joists, beams, stair stringers and posts. FastenMaster ThruLOKs were also used to connect the 4x4 deck railing posts to the 2x joists, and the company’s popular TimberLOKs, HeadLOKs, and FlatLOKs were used to construct the deck’s frame and roof support structure.

“During the construction process, we had many employees visit the jobsite to see how and where our products are used in the market,” said Jennings. “This gave them a much better understanding for the importance of what they do, particularly when you consider how many different structural fasteners we manufacture, and the critical performance requirements for those fasteners. It’s a great educational vehicle for our entire staff.”

About OMG Building Products, LLC.

Founded in 1981 as Olympic Fasteners, OMG Building Products, LLC., is a leading manufacturer and global supplier of fasteners, products and technology for residential construction and commercial roofing applications. The company currently employs over 600 employees globally and is one of the largest employers in western Massachusetts. In addition to its Agawam-based operations, OMG has manufacturing plants in Addison, IL., and Rockford, MN., and a global sales force of over 100 in North America, Europe and Asia. The company produces more than 1.5 billion fasteners annually to support its two operating divisions: OMG Roofing Products and FastenMaster. For additional information, please visit OMGInc.com or call (800) 633-3800.